Ultrapure Water System Types

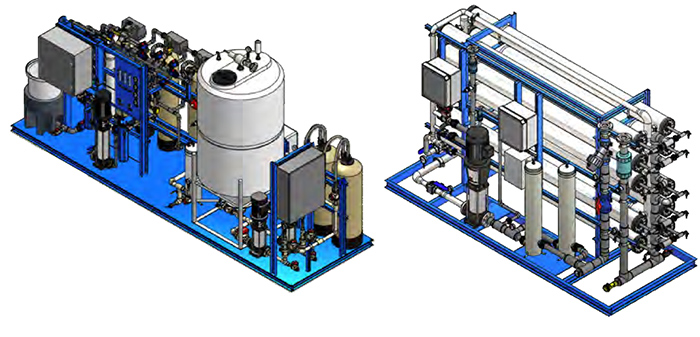

High Flow Centralized Ultrapure Water Treatment Systems

Industrial Water Solutions offers both Low Flow Ultrapure Water Systems and High Flow Ultrapure Water Systems (5-5,000 GPM).

Our High Flow Ultrapure Water systems are been specifically engineered to function as the centralized, high flow rate, purified water source, catering to diverse industries and their unique requirements. Some examples of these industries and needs include:

- Pharmaceutical, Medical, Research Laboratory Ultrapure Water Systems

- Power Generation, Low, Medium and High Pressure Boilers Ultrapure Water Systems

- Food and Beverage, Dairy Ultrapure Water Systems

- Oil and Gas Process Water Ultrapure Water Systems

- Heavy Industrial & Commercial Process Feed Water Ultrapure Water Systems

Ultrapure water systems are engineered to economically produce water with an exceptionally high level of purity by the removal of dissolved minerals, bacteria, particles, and organic impurities. The latest technologies in water ultrafiltration (UF), softener, reverse osmosis (RO), carbon filter, deionization (DI) cartridges, ultraviolet lights, electro-deionization (EDI), and Liqui-Cel degasification are components of these water treatment systems. Ultrapure systems can be constructed using a variety of materials including FRP, lined carbon steel or stainless steel (304, 316, 316L). These water treatment systems produce up to 5,000 GPM and can be skid mounted, pre-piped and pre-wired, mounted in a container, designed to be explosion proof, or made to any engineering specification.

Laboratory, Medical, Diagnostic Pre-packaged Ultrapure Water Treatment Systems

Industrial Water Solutions Ultrapure Lab Water Systems are designed to serve as an all inclusive, validated purified water system with an extremely small footprint for a variety of applications such as:

- Laboratory, Healthcare & Medical Facilities

- Clinical Diagnostics & Analyzers

- Research, Testing & Academic

- Centralized Distribution for ultrapure water systems

Ultrapure water (UPW) systems meet or exceed the Type I, II, III reagent-grade water platforms set forth by CAP/NCCLS, ASTM United States Pharmacopeia (USP), European Pharmacopeia and Japanese Pharmacopeia standards. All water treatment components such as reverse osmosis (RO), carbon filter, water softener, deionization (DI) cartridges, ultraviolet lights, ultrafiltration and electrodeionization (EDI) are installed, wired, piped and tubed in a factory-tested, validated enclosure perfect for above or below a lab counter or on lab floor to minimize installation time, footprint and start-up costs. Systems produce a few liters per hour (lph) to 100s of liters per minute (lpm)